Services

Independent flatness measurement with the latest 3D laser technology

Industrially manufactured floors, such as those installed in industrial halls with high-bay warehouses, must meet the highest demands in terms of evenness. Even small deviations from flatness can have an unfavorable effect on the use of industrial floors. That is why there is a series of DIN standards that regulate the evenness of floors. Builders and general contractors can have the flatness evaluation prescribed therein carried out at BPL24 using modern laser measurement technology. We offer the highest precision and fast data collection using 3D laser scanners.

What is a flatness measurement used for?

An evenness measurement of the floor is part of some DIN standards (e.g. DIN 18202, DIN 15185) for industrial and building construction and must therefore be observed by many builders and general contractors. A floor that is as flat as possible ensures that forklifts can drive in the hall with as little disruption as possible. In the case of high-bay warehouses, a floor within the evenness tolerance is particularly important in order to prevent the shelves from being crooked. With a perfectly level floor, you can occupy all levels of shelving without having to worry about accessibility. A flatness measurement is therefore of great importance for industrial floors in order to avoid later influencing of the work processes or subsequent improvements.

Measure industrial floors faster thanks to modern technology

The conventional flatness measurement is carried out by hand: A grid is applied to the hall floor and the gauge is measured at defined points with a ruler or gauges. The disadvantage of this is that on-site measurements are very time-consuming and can take several months in large halls. For this reason, often only a small part of the hall is measured and the resulting flatness deviations are projected onto the entire hall.

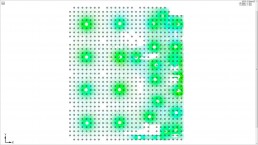

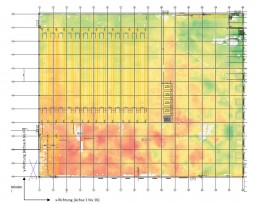

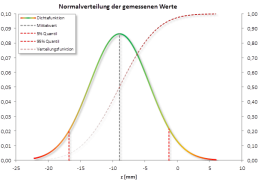

The solution for faster and more accurate measurements lies in the laser-assisted flatness measurement from BPL24: A 3D laser scanner, which is otherwise used, for example, in the inventory of buildings or in line construction, measures the hall floor. Using software developed in-house, BPL24 can use this to create flatness reports. Not only individual points or sub-areas are measured, but the entire hall floor: In this respect, our method goes beyond the requirements of the DIN standards and offers greater security: Exceeding of flatness tolerances are detected with greater probability than with conventional methods. In addition, the laser-based measurement method is faster than the standard method. The evenness of up to 15,000 square meters of hall floor can be measured on site in one working day.

Your advantages when measuring flatness with the BPL24

What makes the BPL24 laser-based flatness evaluation better than conventional methods? Our modern process scores particularly well because of the higher data quality and quantity.

Specifically, you have the following advantages:

- Very fast measurement: Up to 15,000 square meters of hall floor can be measured in one working day

- Detailed evaluation: Thanks to modern technology, the grid for evaluation is much more precise than with conventional flatness evaluation using a ruler and folding rule

- Equipped for all requirements: Thanks to the computer-aided evaluation, later inquiries (e.g. other DIN standards) can also be processed without having to take new measurements.

- Measurements can also be carried out later: Even if there are already shelves in the hall, the laser measurement of the evenness of the floor is possible.

Have we piqued your interest?

If you have an industrial floor to measure or need a flatness measurement according to DIN, we are happy to be there for you! Contact us and we will make you an individual offer.