Hardened concrete tests

Services

hardened concrete tests

| standard / guideline | designation |

| EN 480-11 | Determination of air void parameters in hardened concrete |

| DAfStb guideline “Steel fiber concrete” | Determination of the performance classes of steel fiber reinforced concrete |

| Model code 2010 / DIN EN 14156 | Determination of the limit of proportionality and the residual flexural strength |

| DBV leaflet “Steel fiber concrete” | Determination of the fiber concrete classes of steel fiber concrete |

| SIA 162/6 “steel fiber concrete” | Determination of the calculated value of the effective flexural strength (according to Swiss standard) |

| ÖVBB guideline “Fiber concrete” | Determination of the fiber concrete classes (according to Austrian standard) |

| EN 14651 | Determination of the residual flexural strength |

| EN 12390-3 | Determination of the compressive strength on a cube |

| EN 12390-3 | Determining the compressive strength of a cylinder |

| EN 447 | Determination of the compressive strength of a cylinder made of grout |

| EN 12504-1 | Determination of the compressive strength of a drill core |

| ZTV concrete | Determination of the compressive strength of a cement concrete drill core |

| Determination of the compressive strength on a prism (4x4x16 cm) made of mortar/screed/cement | |

| EN 12390-5 | Determination of the flexural strength on a flexural beam |

| Determination of the flexural strength on a prism (4x4x16 cm) made of mortar/screed/cement | |

| EN 12390-6 | Determination of splitting tensile strength on a cube |

| EN 12390-6 | Determination of splitting tensile strength on a cylinder |

| EN 12390-7 | Determination of the hardened concrete bulk density on a cube |

| EN 12390-7 | Determination of the hardened concrete bulk density on a drill core or cylinder |

| EN 12390-7 | Determination of the hardened concrete bulk density on a flexural beam |

| Determination of the hardened concrete bulk density using a prism (4x4x16 cm) made of mortar/screed/cement | |

| EN 12390-8 | Determination of the water penetration depth on a cube |

| EN 12390-8 | Determination of the water penetration depth on a test specimen |

| DIN CEN/TS 12390-9 | Determination of the freeze-thaw resistance (plate test method) |

| DIN CEN/TS 12390-9 | Determination of the freeze-thaw resistance (CDF test method) |

| DIN prEN 12390-13 | Determination of the modulus of elasticity under pressure (secant modulus) |

| DIN 1048-5 | Determination of the static modulus of elasticity (chord modulus) |

fresh concrete tests

Services

fresh concrete tests

| standard / guideline | designation |

| DIN 1048-1 | Determination of the fresh concrete temperature |

| EN 12350-2 | Determination of the slump |

| EN 12350-4 | Determination of the degree of compaction |

| EN 12350-5 | Determination of the slump |

| EN 12350-6 | Determination of the fresh concrete bulk density |

| EN 12350-7 | Determination of the air content (pressure method) |

| EN 12350-8 | Determination of the slump flow on SCC |

| EN 12350-8 | Determination of the flow time t500 at SVB |

| EN 12350-9 | Determination of the outlet funnel flow time at SVB |

| EN 12350-10 | Determination of the flowability on SVB (L-box) |

| EN 12350-11 | Determination of the sedimentation stability in the sieve test (segregation) on SCC |

| EN 12350-12 | Determination of the degree of locking tendency at SVB |

| EN 12350-12 | Determination of the slump in the blocking ring test on SVB |

| EN 12350-12 | Determination of the flow time t500J in the blocking ring test on SVB |

| EN 12390-2 | Production and storage of cubes |

| EN 12390-2 | Manufacture and storage of cylinders |

| EN 12390-2 | Manufacture and storage of flexural beams |

| EN 12390-2 | Manufacture and storage of prisms |

| DAfStb-Rili “steel fiber concrete” | Determination of the steel fiber content in fresh concrete (washout test) |

| DBV leaflet (BF) 2007 | Determination of the w/c value of a fresh concrete sample (dry drying test) |

| Flat-rate monitoring for ÜK II / III construction sites |

flatness measurement

Services

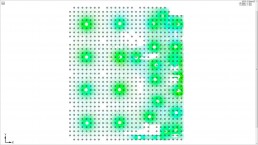

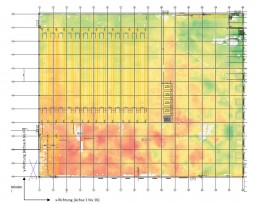

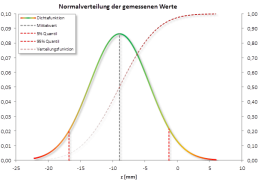

Independent flatness measurement with the latest 3D laser technology

Industrially manufactured floors, such as those installed in industrial halls with high-bay warehouses, must meet the highest demands in terms of evenness. Even small deviations from flatness can have an unfavorable effect on the use of industrial floors. That is why there is a series of DIN standards that regulate the evenness of floors. Builders and general contractors can have the flatness evaluation prescribed therein carried out at BPL24 using modern laser measurement technology. We offer the highest precision and fast data collection using 3D laser scanners.

What is a flatness measurement used for?

An evenness measurement of the floor is part of some DIN standards (e.g. DIN 18202, DIN 15185) for industrial and building construction and must therefore be observed by many builders and general contractors. A floor that is as flat as possible ensures that forklifts can drive in the hall with as little disruption as possible. In the case of high-bay warehouses, a floor within the evenness tolerance is particularly important in order to prevent the shelves from being crooked. With a perfectly level floor, you can occupy all levels of shelving without having to worry about accessibility. A flatness measurement is therefore of great importance for industrial floors in order to avoid later influencing of the work processes or subsequent improvements.

Measure industrial floors faster thanks to modern technology

The conventional flatness measurement is carried out by hand: A grid is applied to the hall floor and the gauge is measured at defined points with a ruler or gauges. The disadvantage of this is that on-site measurements are very time-consuming and can take several months in large halls. For this reason, often only a small part of the hall is measured and the resulting flatness deviations are projected onto the entire hall.

The solution for faster and more accurate measurements lies in the laser-assisted flatness measurement from BPL24: A 3D laser scanner, which is otherwise used, for example, in the inventory of buildings or in line construction, measures the hall floor. Using software developed in-house, BPL24 can use this to create flatness reports. Not only individual points or sub-areas are measured, but the entire hall floor: In this respect, our method goes beyond the requirements of the DIN standards and offers greater security: Exceeding of flatness tolerances are detected with greater probability than with conventional methods. In addition, the laser-based measurement method is faster than the standard method. The evenness of up to 15,000 square meters of hall floor can be measured on site in one working day.

Your advantages when measuring flatness with the BPL24

What makes the BPL24 laser-based flatness evaluation better than conventional methods? Our modern process scores particularly well because of the higher data quality and quantity.

Specifically, you have the following advantages:

- Very fast measurement: Up to 15,000 square meters of hall floor can be measured in one working day

- Detailed evaluation: Thanks to modern technology, the grid for evaluation is much more precise than with conventional flatness evaluation using a ruler and folding rule

- Equipped for all requirements: Thanks to the computer-aided evaluation, later inquiries (e.g. other DIN standards) can also be processed without having to take new measurements.

- Measurements can also be carried out later: Even if there are already shelves in the hall, the laser measurement of the evenness of the floor is possible.

Have we piqued your interest?

If you have an industrial floor to measure or need a flatness measurement according to DIN, we are happy to be there for you! Contact us and we will make you an individual offer.

nonlinear FE calculation

Services

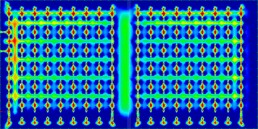

nonlinear FE calculation

Our experienced engineers work on a wide variety of problems and questions in the field of steel fiber concrete, reinforced concrete and combination reinforced components. In order to provide our customers with the most economical results possible, the models are defined and calculated using non-linear material laws. The latest hardware and software is used, which helps us to solve customer inquiries cleanly and quickly.

Planning & Consulting

Services

planning

We are both a building material testing laboratory and an engineering office specializing in the testing and design of steel fiber reinforced concrete. Through many years of experience with this special building material, we offer

- Economic analysis of industrial floors

- Elaboration of concrete technology concepts

- Static design of concrete components (unreinforced concrete, steel fiber concrete, reinforced concrete, combined reinforcement) according to Eurocode 2 and the DAfStb guideline “steel fiber concrete”

- Optimization of industrial panels

- Development of after-treatment concepts

- Damage analysis or cause determination on the structure / inventory

- Elaboration of rehabilitation concepts

- Preparation of expert opinions / damage reports

Services

advisory

- construction-related consultancy

- Advice on individual design problems in concrete construction (reinforced concrete, steel fiber concrete)

- Training / lectures on Eurocode 2 (DIN EN 1992-1-1) in connection with the “steel fiber reinforced concrete” guideline from the DAfStb